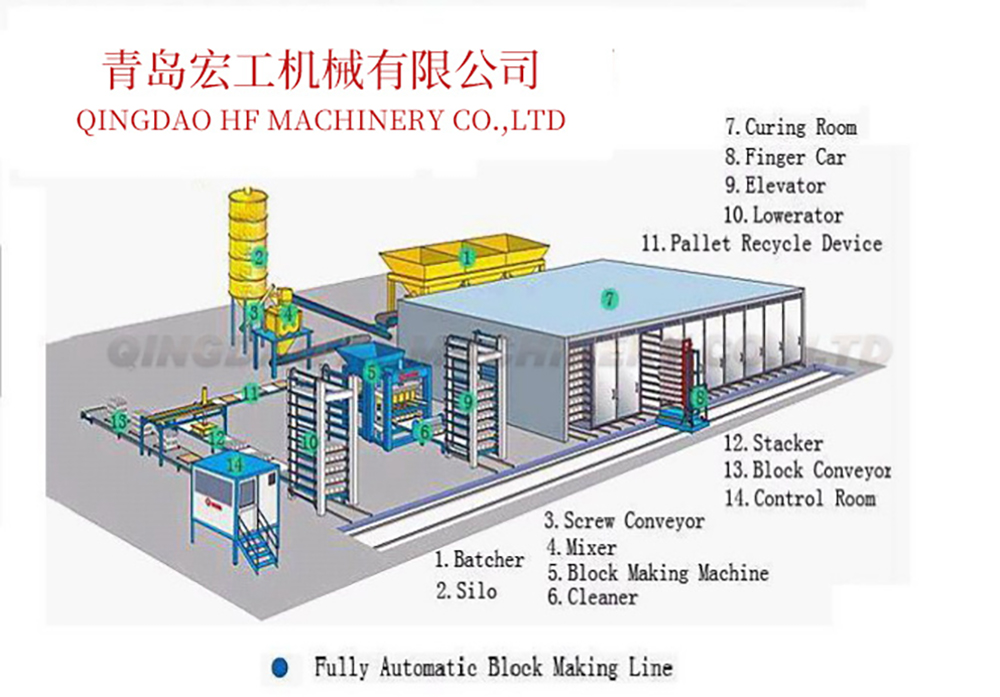

Finger Car systems are a type of system that has become increasingly common in recent years and provides advantages in the production costs of many companies. It is known as one of the transfer methods between production units.

Since Finger Car systems have a structure that reduces the workforce in terms of their general features; It provides the opportunity to benefit from as much robotic capability as possible from manufacturing processes. The system, which continues to be used in briquette production facilities, can be used to transport pallets containing all kinds of blocks consisting of aggregate or mortar mixture, or stacking different materials.

In the production network formed by block producing machines, one of the units that needs manpower the most is the transfer transport area. The reasons such as the heavy weight of the produced blocks and the access to a large number of mass production materials prevent the transportation of concrete blocks in a fast and regular shape.

The finger car system resembles a robotized depiction of a human being with both hands stretched out at a 90o angle to the ground. For this reason, it is possible to carry out transportation together with the ability provided by the deep “U” shape formed between the two arms.

The system, which performs more than transporting individual concrete units, receives a large number of concrete blocks molded on pallets between production units and delivers them to the right hopper.

Continuing to work with the aim of becoming a world brand in the production of block production machines, Globmac products include finger car system. Globmac production of the system, which operates as a transfer unit through its arms; KB FNC Elewator appears as Lowarator Finger Car Racking System.

If you want to have this system and use it in your various projects, you can consult us. To access the current price list and technical specifications of the product, you can contact us at Globmac contact addresses.

Since the Finger system carries on pallets; It carries out its operations with its job description in an area between the shelves room and the machine line. During these processes, it provides robotic service with 16 different pallet handling capacity at a time.

The liquid saturation of the products obtained during transportation is transported with different alternative reservoirs within the finger car system. For this stage of the system, technical information can be requested in the market as wet product (elevator) and dry product (levator).

The advantages of the system show itself both in the field of labor and cost, and in the field of speed with the possibility of mass production. Within this system, which offers the opportunity to work with the footless pallet model included in the system; The mechanisms that finger car picks up and leaves the pallets perform the main function.

Continuing to supply concrete and briquette production facilities around the world with the motto of HF Block Machine; continues its services with its wide product range. You can have the finger car system, which is outside of the concrete and briquette production units, with HF quality.

If you want to get detailed information about the system, which is among the HF products; You can make calls under the name KB FNC Elewator, Lowarator Finger Car Rack System, reach us from HF contact addresses, and you can access both up-to-date price information and technical information from our expert staff.

Back To The List

The Molding Vibration Block Machine has a short forming cycle and high production output. The continuous increase in vibration frequency during material feeding and forming vibrations reduces the feeding time by 3 to 4 seconds. The table vibration machine

Brick manufacturing has been an essential part of construction for centuries, providing durable and aesthetically pleasing building materials. However, the process of producing bricks is not without its challenges. As the world becomes more environmentall

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

Gemini Tower, Block B, Chunyang Road, Chengyang District, Qingdao, China

Show on the Map

We will contact you within 24 hours.