The raw materials of concrete bricks mainly include cement, sand, aggregate and water. The process of selecting and matching these raw materials is as follows:

1. Select cement: Cement is the cementing material of concrete. Commonly used cements include ordinary Portland cement, slag cement, and cement for high-performance concrete. Different types and grades of cement are selected according to factors such as concrete strength grade, ambient temperature, and construction technology.

2. Select sand: sand is the fine aggregate of concrete, the key to selecting sand is to ensure that its particle size is appropriate. In general, the sand used for concrete should be fine sand with a particle size between 0.15-2.5mm, which has good filling and water permeability.

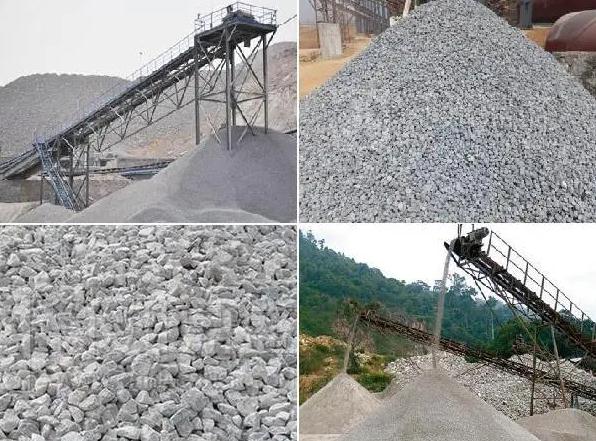

3. Select aggregate: Aggregate is the coarse aggregate of concrete. Commonly used aggregates include gravel and pebbles. The selection of aggregate needs to be considered comprehensively based on factors such as concrete strength grade, construction technology, and aggregate quality. Generally, the aggregate used in concrete should be coarse aggregate, with a particle size between 5-10mm, which has good mechanical properties. performance.

Concrete aggregate refers to the granular loose material that acts as a skeleton or filling in concrete. Coarse aggregate and fine aggregate. Coarse aggregate refers to pebbles, crushed stones, etc., and fine aggregate refers to natural sand, artificial sand, etc.

The Molding Vibration Block Machine has a short forming cycle and high production output. The continuous increase in vibration frequency during material feeding and forming vibrations reduces the feeding time by 3 to 4 seconds. The table vibration machine

Brick manufacturing has been an essential part of construction for centuries, providing durable and aesthetically pleasing building materials. However, the process of producing bricks is not without its challenges. As the world becomes more environmentall

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

Gemini Tower, Block B, Chunyang Road, Chengyang District, Qingdao, China

Show on the Map

We will contact you within 24 hours.