Installation, repair and maintenance of your brick machine steps breakdown:

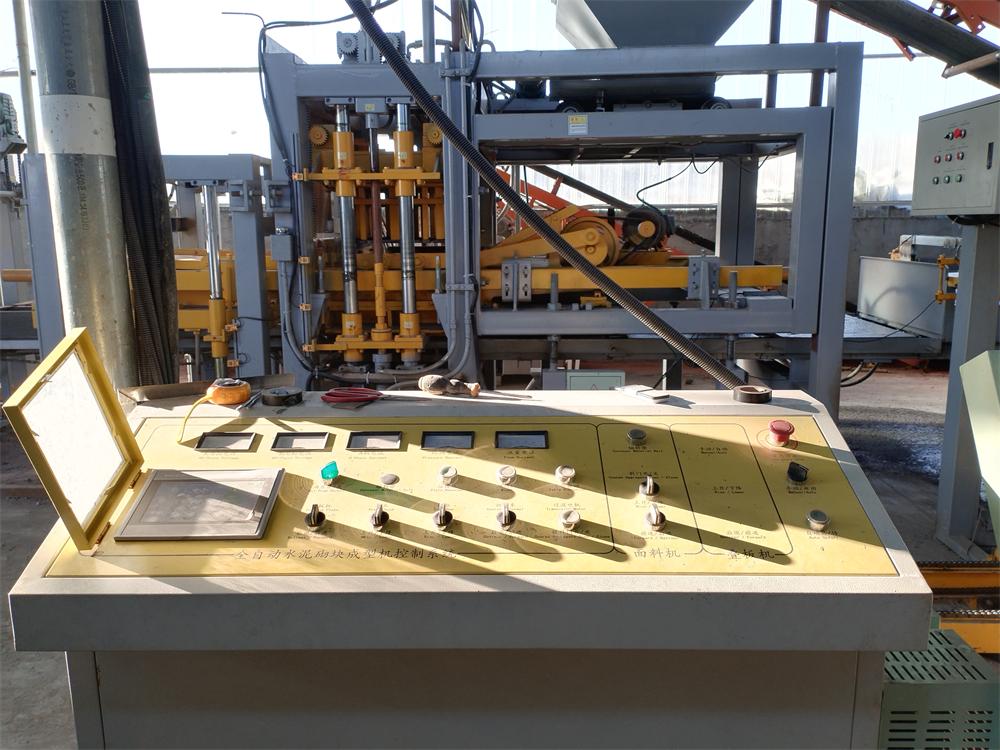

1) Install the brick machine: install according to the instructions and drawings. First of all, choose a stable ground, install the base, install the machine body, connect the power cord and oil pipe, check the tightness of each part, adjust the operating parameters and sensor position, and conduct a trial run after confirming that it is correct.

2) Maintenance of brick machine: Regular inspection and maintenance, and timely replacement or repair of problematic parts. Some wearing parts need to be replaced regularly, such as motor bearings, gears, belts, etc. Regularly clean the dust and residue inside the machine to keep it clean and tidy. If the machine is faulty, check it in time and take appropriate maintenance methods.

3) Maintain the brick machine: The key to maintaining the brick machine is to keep it clean and lubricated. Regularly clean the sundries and stains on the outside and inside of the machine, and replace the lubricating oil and grease in time. At the same time, pay attention to the use of appropriate lubricants and greases to avoid damage to machine parts.

The Molding Vibration Block Machine has a short forming cycle and high production output. The continuous increase in vibration frequency during material feeding and forming vibrations reduces the feeding time by 3 to 4 seconds. The table vibration machine

Brick manufacturing has been an essential part of construction for centuries, providing durable and aesthetically pleasing building materials. However, the process of producing bricks is not without its challenges. As the world becomes more environmentall

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

Gemini Tower, Block B, Chunyang Road, Chengyang District, Qingdao, China

Show on the Map

We will contact you within 24 hours.