The manufacturing process of concrete blocks involves several steps to produce durable and consistent building blocks used in construction. Here is an overview of the typical process:

Raw Materials Preparation:The primary raw materials used in concrete block manufacturing are cement, aggregates (such as sand, gravel, or crushed stone), and water. Sometimes, additives like fly ash, slag, or chemical admixtures are also included to enhance specific properties of the blocks.

Mixing:The raw materials are mixed together in a concrete mixer to create a homogenous mixture. The proportions of cement, aggregates, and water are carefully controlled to achieve the desired consistency and strength.

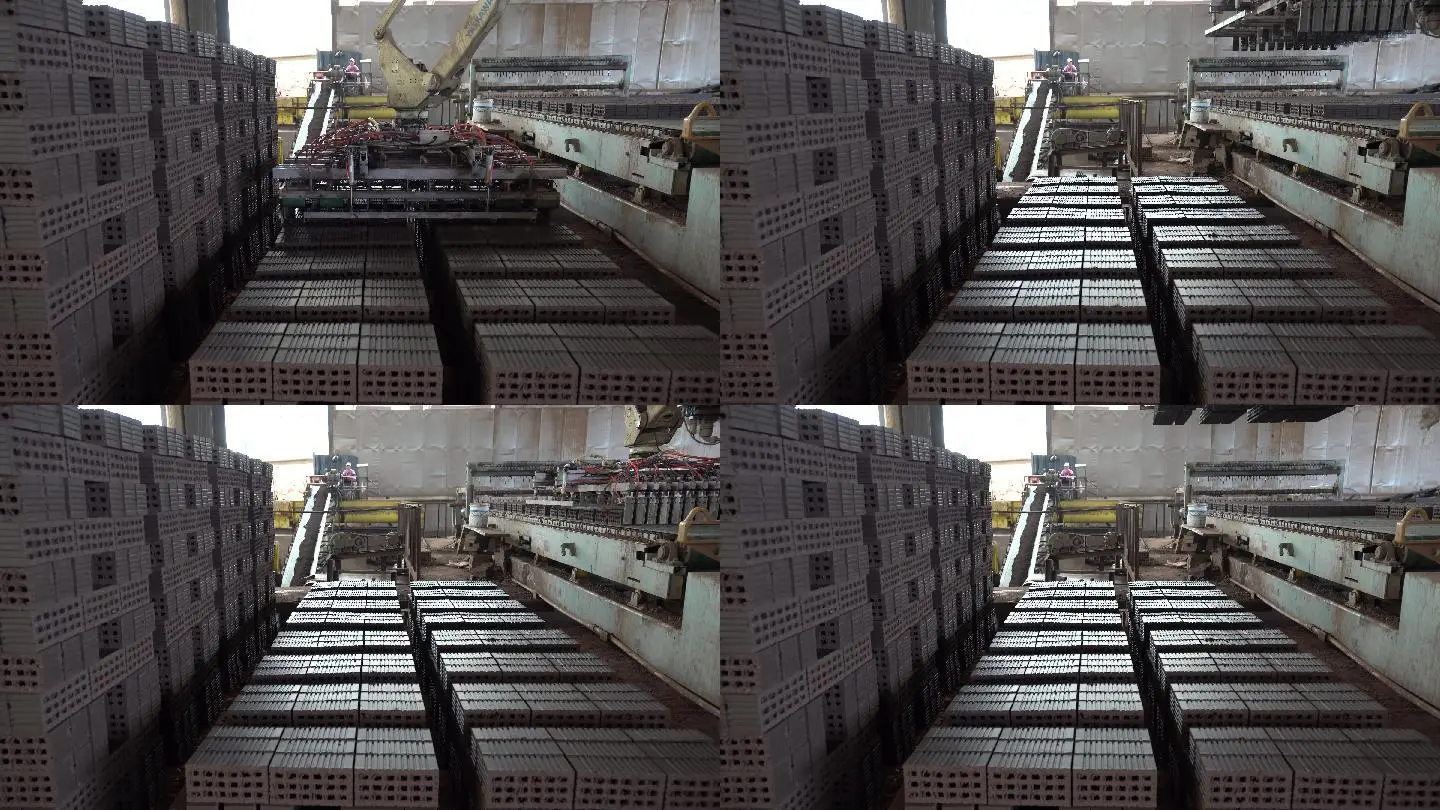

Forming the Blocks:The mixed concrete is then transferred to a block-making machine. There are various types of machines used for this purpose, including automatic, semi-automatic, and manual machines. These machines use molds to shape the concrete mixture into block forms. The molds can have various designs and sizes to produce different types of blocks.

Compaction and Vibrocompression:Once the concrete mixture is placed into the molds, the machine applies compaction and vibration to ensure that the mixture is evenly distributed within the mold and to eliminate air pockets. This process enhances the density and strength of the blocks.

QT15-15 automatic block making machine adopts articular storage and description material system to insure the feeding accuracy and avoiding the effect of exterior material. So the products have high density. Adopting synchronization vibration insures the products making average. Combine with long-distance controlling system, it can achieve scrutiny, controlling, diagnosis It doesn’t need a professional person but only need a simple training to the operator. It produces various bricks/blocks etc.

Curing:After the blocks are formed, they need to be cured to develop their strength and durability. Curing involves maintaining proper moisture and temperature conditions for a specific period. This can be done using methods such as steam curing, water curing, or air curing.

The Molding Vibration Block Machine has a short forming cycle and high production output. The continuous increase in vibration frequency during material feeding and forming vibrations reduces the feeding time by 3 to 4 seconds. The table vibration machine

Brick manufacturing has been an essential part of construction for centuries, providing durable and aesthetically pleasing building materials. However, the process of producing bricks is not without its challenges. As the world becomes more environmentall

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

Gemini Tower, Block B, Chunyang Road, Chengyang District, Qingdao, China

Show on the Map

We will contact you within 24 hours.