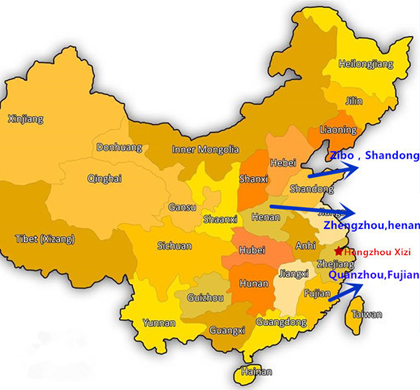

Global Cases

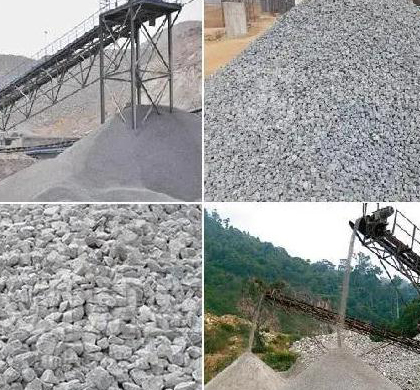

The raw materials of concrete bricks mainly include cement, sand, aggregate and water. The process of selecting and matching these raw materials is as follows:

To make high quality bricks, you will need to follow a few basic steps:

Installing a brick machine involves setting up the machine properly on a level surface and ensuring that it is stable and secure. Follow these steps to install a brick machine:

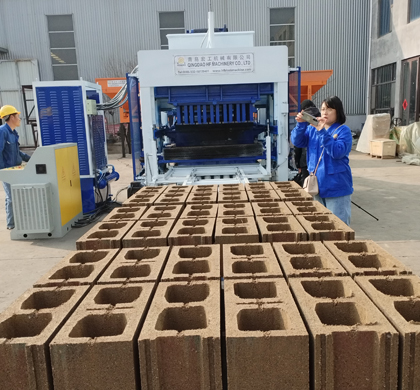

In short, you need to consider your own budget, production needs and energy environment. At the same time, you need to choose a brick making machine with good quality, stable performance and easy maintenance.

Choosing a reliable brick making machine supplier is an important decision that can impact the quality of your final product and the success of your business. Here are some factors to consider when selecting a reliable brick making

Hollow blocks, also known as concrete blocks, are commonly used in construction for building walls, foundations, and other structures. Here are the general steps to manually make hollow blocks:

Hollow block manufacturing can be a profitable business, but the profitability depends on various factors such as market demand, competition, production cost, pricing, and marketing strategies.

It's easy to find a manufacturer of block- making machine manufacturer from the net, like Google, Facebook, Twitter, Alibaba etc.

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

Gemini Tower, Block B, Chunyang Road, Chengyang District, Qingdao, China

Show on the Map

We will contact you within 24 hours.